MATERIAL ANALYTICS IN THE AREA

Refractory Materials and Raw Materials

Refractory materials are inorganic non-metallic substances or products that are resistant to heat and fire. The main components of refractory materials include, besides carbon and silicon carbide (SiC), various oxides such as aluminum oxide or magnesium oxide. The primary use of refractory materials is in furnace construction. The installation of refractory bricks or furnace linings is not limited to the iron and steel industry but also extends to the glass, aluminum, cement, and ceramic industries.

Both the analysis of the raw materials for refractory bricks and the composition of the finished products are of crucial importance in an industry dealing not only with high temperatures but also, in some cases, with molten materials. A furnace breakthrough due to improperly manufactured refractory bricks is the worst-case scenario for any refractory supplier.

We analyze your refractory raw materials and finished products so that you can ensure high performance for your customers.

Depending on the type and use of binders in the manufacture of refractory materials, issues such as odor nuisance, hazards to employees and the environment, or production errors during the curing process may arise.

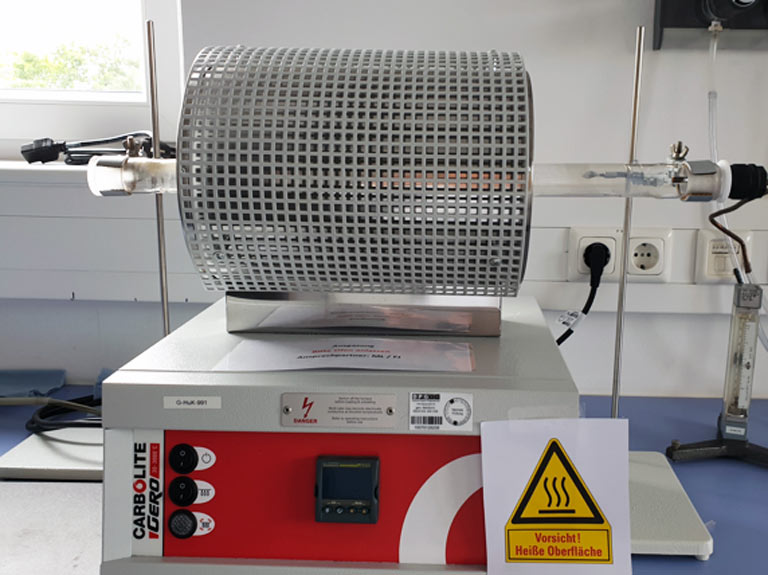

Through outgassing tests in a tube furnace under various atmospheres and by analyzing the gases in different solvents, we can determine the composition of the binder.

XRF

Sieve analysis

Heating microscopy

GC-MS screening

XRD

For enquiries about these analyses, please contact our laboratory team at anfrage@industrial-lab.de or get in touch with your contact person:

Head of department

Inorganics / Sample Preparation

02762 9740 - 74

Send e-mail

Head of Team Inorganics

02762 9740 - 93

Send e-mail

Inorganics

02762 9740 - 85

Send e-mail

Head of department

Organics / REM

02762 9740 - 28

Send e-mail

Materials are said to be refractory if their softening point is higher than 1500°C.

Refractory materials or raw materials are, for example, mullite, corundum and chrome ore sand.

There are refractory metals such as platinum, iridium, rhodium, ruthenium and osmium.