Surfaces & Coatings-ANALYTICS IN THE AREA

Salt spray & corrosion change tests

Salt spray and alternating corrosion tests are standardized test methods for evaluating the corrosion resistance of materials and coatings, particularly in the automotive, aviation, defense, and construction industries. The focus of these test methods is to assess the quality of components under extreme (climatic) conditions.

In addition to testing the functionality of the components themselves, they may also be coated for various reasons, and the coatings can be tested. A rough distinction is made between two types of coating: functional, technical coating and decorative coating.

In the technical field, the purpose of the coating is to protect the substrate from corrosion. The focus of the coating is therefore on its function.

The situation is different with decorative coatings. Here, the appearance must be right: shiny surfaces, color effects, perfect feel. All of this should underline the value of the product and keep it looking good for as long as possible.

Both test procedures are designed to simulate extreme environmental conditions and thus certify corrosion resistance.

Coated components are subjected to a wide variety of stresses in daily use. While metallic coatings are sensitive to the chloride in the test solution used in salt spray testing, organic coatings are more susceptible to attack from moist heat. The requirements for technical coatings are also different from those for decorative coatings. We have a suitable test for every type of stress, which puts the component through its paces to ensure that there are no problems in later use:

Salt spray test

Alternating corrosion test

CASS test

ESS / AASS test

The neutral salt spray test or salt spray test is an established standard procedure for evaluating corrosion resistance. Colloquially known as the salt spray test, NSS, or salt fog test, it forms the basis of many corrosion procedures. It simulates a salty environment, such as in maritime applications or in logistics operations under winter conditions. The neutral salt spray test is particularly suitable for comparative testing in the context of material qualification and product approval. Within short testing times, reliable statements can be made about the suitability of components for military or industrial use:

Metallic substrates with organic layers

Metallic substrates with metallic layers

Plastic substrates with metallic layers

Components for offshore use

Testing according to DIN, ASTM, or MIL-STD

Due to increasing demands to components, coatings have become increasingly high-quality, e.g. alloy layers, zinc flakes, flake coatings, and complex coating systems with multiple nickel layers. Sophisticated coatings require sophisticated tests.

The corrosion cycle test simulates the actual stress experienced by components during their subsequent service life. In the salt spray phase, the components are exposed to a salt solution, which wets the surfaces and crystallizes in the subsequent warm-dry phase. The salt is then “reactivated” in the warm-humid phase and acts on the surface of the components. These cycles of varying stress are repeated continuously.

The corrosion cycle test provides realistic corrosion patterns and progression, enabling a precise evaluation of material and coating performance. By specifically targeting the subsequent installation situation, components can be tested and qualified with pinpoint accuracy in terms of their suitability for specific operating conditions:

Metallic substrates with organic layers

Metallic substrates with metallic layers

Plastic substrates with metallic layers

The acronym CASS stands for copper accelerated acetic acid salt spray test. In contrast to the classic salt spray test, the test solution is additionally enriched with acetic acid and copper(II) chloride. The acetic acid lowers the pH value to a slightly acidic range, while the copper ions act as a catalyst and significantly accelerate the corrosion reactions. Another stress factor is the increased test temperature of 50°C, which further increases the reaction speed and intensifies the stress on the test specimens. This combination of chemical aggressiveness and thermal stress is primarily used for rapid and efficient weak point analysis and, unlike cyclic corrosion tests, does not simulate real-life conditions:

Painted aluminum substrates

Plastic substrates with copper-nickel-chrome coating

Zinc diecasting with copper-nickel-chrome coating

In the ESS or AASS (acetic acid salt spray test), the pH value of the salt solution is set to a slightly acidic range. This, together with the addition of acetate ions, places additional stress on the test specimens. While the acetic acid salt spray test was initially used primarily for components in the sanitary sector to consider the use of acetic acid cleaners, it is now also used in the automotive, printing roller, and cutlery sectors. Nickel coatings or stainless steels with nickel as an alloying element can be sensitive to acetate ions.

Components from the sanitary sector

Piston rods, printing cylinders

Zinc die casting with copper - nickel - chrome coating

The various salt spray methods are used to evaluate the corrosion resistance of materials and coatings under different conditions. Corrosion in the real world is caused by many different environmental influences such as salt, moisture, temperature, acidic gases, or dirt, which is why there are also many different methods that simulate a specific type of stress.

For enquiries about these analyses, please contact our laboratory team at anfrage@industrial-lab.de or get in touch with your contact person:

Head of Laboratory

0212 22147 - 0

Send e-mail

Electroplating technician

0212 2214 - 75

Send e-mail

phys. Technical Assistant Metallography

0212 2214 - 75

Send e-mail

In the salt spray test, we spray a 5% sodium chloride (NaCl) solution. Sodium chloride (NaCl) is commonly known as table salt. However, you should avoid using common household salt as far as possible, as other ionic components such as fluoride are sometimes added and it often contains anti-caking agents. We use sodium chloride with a purity of at least 99.5%, which we buy with a certificate from specialist retailers. We completely dissolve 50 g of sodium chloride per liter of test solution. This is important so that small crystals do not clog the hoses or block the fine spray nozzle.

Traditionally, metallic coatings are tested in the salt spray test. However, organic coatings such as powder or dip coatings as well as CDP on steel or other metallic substrates are also tested in the salt spray test. Here, the quality of the coating process is tested by applying a defined scratch mark through the coating onto the substrate.

We test technical coatings on components with hard chrome, electroless nickel, zinc or zinc alloy coatings (zinc-nickel, zinc-iron), zinc flake, hot-dip galvanized and various paints as well as passivations or conversion coatings, such as anodizing. We also test decorative coatings and coating systems on fittings and decorative parts, such as copper - nickel - chrome or PVD coatings in the salt spray test. The applications are diverse, but a metallic component must be present - either the substrate or the coating

A salt spray test, also known as a salt spray test, is a standardized procedure for evaluating the corrosion resistance of materials and coatings. Here are the main steps:

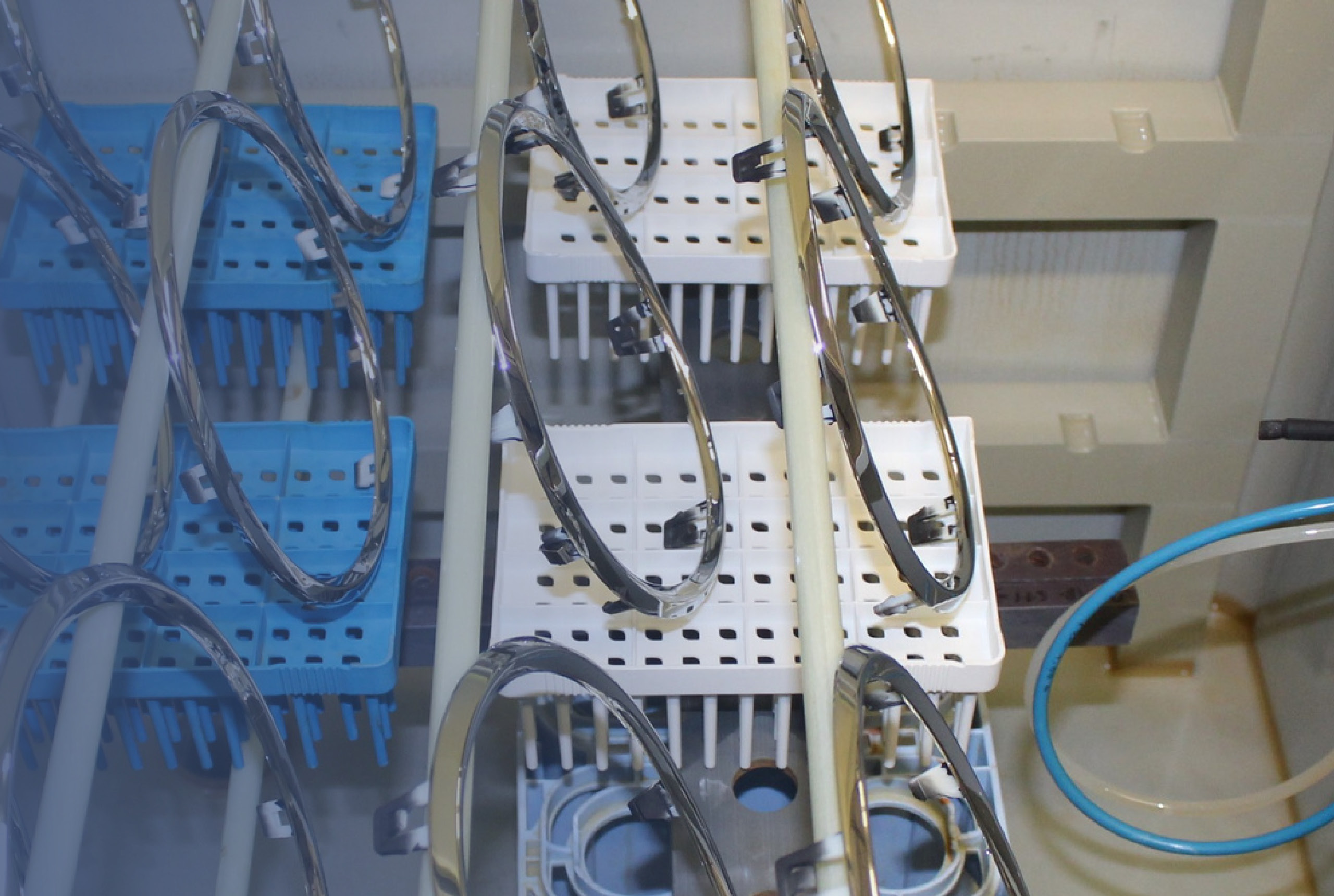

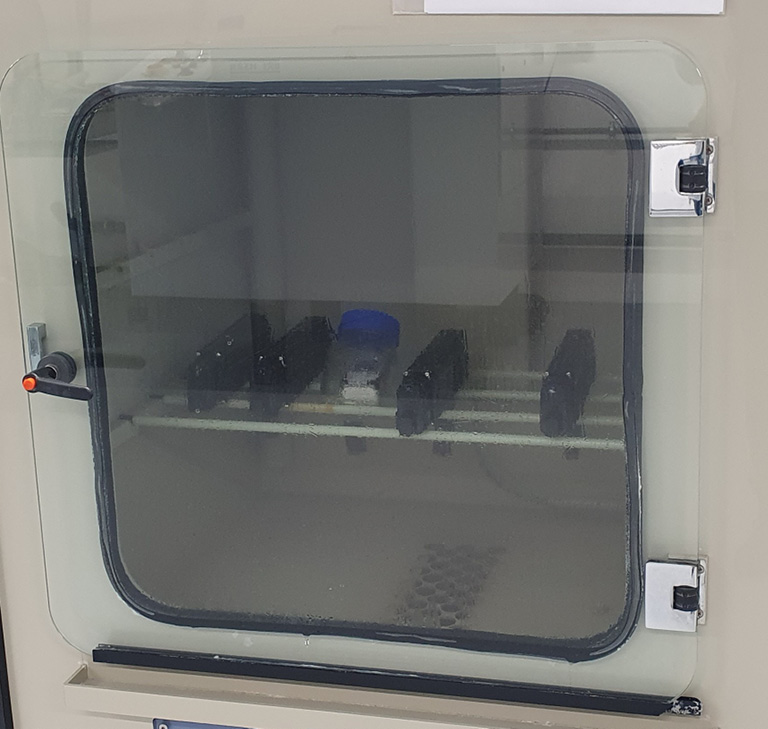

Preparation of the samples: The workpieces to be tested are cleaned and placed in a special test chamber.

Generation of the salt fog: A 5% sodium chloride solution (saline solution) is sprayed in the chamber to create a corrosive atmosphere.

Test conditions: The chamber is maintained at a constant temperature of approximately 35°C and the salt solution is sprayed continuously.

Test duration: The duration of the test can vary from a few hours to several thousand hours, depending on the requirements of the test.

Evaluation of the results: At the end of the test, the samples are examined for signs of corrosion such as rust, blistering and infiltration of the coating.

The salt spray test is often used in the automotive, construction and mechanical engineering industries to check the quality and durability of coatings and materials.