Materialprüfung

Steels and metal alloys are used in everything from medical cannulas, implants and prostheses to construction materials in gigantic buildings. Ceramic materials are very temperature-stable and are used for thermal insulation in the production of these same steels or other high-temperature processes. These range from the manufacture of glass containers to waste incineration. As diverse as the applications are, the quality specifications for the materials are also very variable.

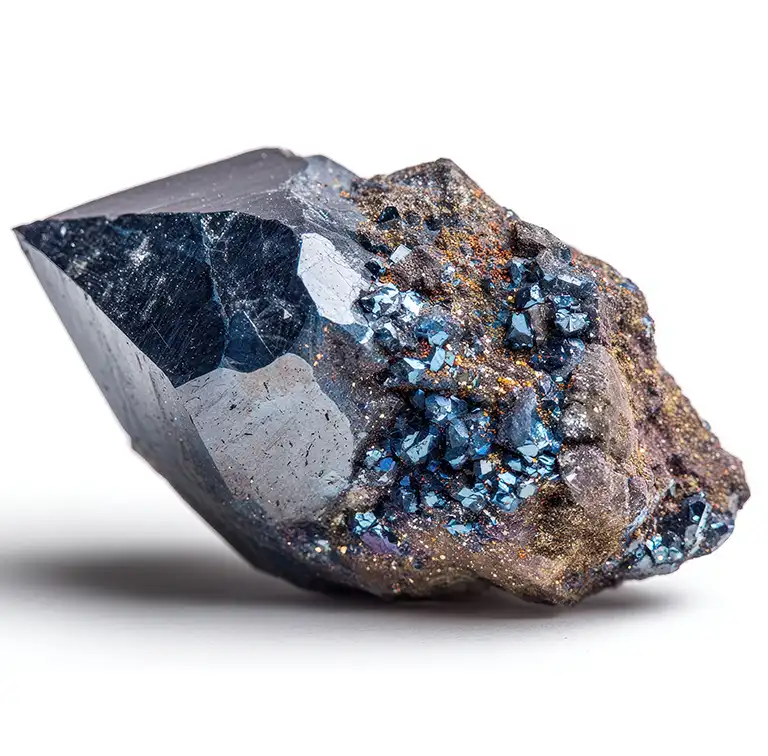

Naturally occurring minerals are found in nature in a solid crystalline structure. Examples are magnesite, dolomite, bauxite and many others. Ores are naturally occurring rocks that contain metallic compounds from which pure metals can be extracted by smelting.

Oxides are chemical compounds of a metal or non-metal with oxygen. A well-known example is rust or iron oxide as a compound of iron with oxygen.

Oxide materials, which are deliberately created by chemical reactions or naturally occurring and mined minerals, are used in industry in many different areas.

In high-temperature processes such as waste incineration, the cement and steel industries, refractory materials are used as an insulating layer in rotary kilns or steel ladles.

Other oxide products are building materials such as cement and concrete, as well as glass and ceramics.

Typical analysis methods for oxide materials are

X-ray fluorescence analysis (XRF)

X-ray diffraction (RBA / XRD)

Determination of metallic iron

Steel is one of the oldest and most important materials known to man and can be recycled almost indefinitely.

There are countless types of steel with specific compositions and correspondingly different properties, depending on the desired area of application.

Unalloyed steel, for example, is used as structural steel in load-bearing structures. Alloyed steels are used as tool steel or as corrosion-resistant stainless steels. High-alloy steels for aerospace applications offer the necessary strength and toughness even at low temperatures.

Typical analysis methods for steels are

Spark spectroscopy (spark OES)

X-ray fluorescence analysis (XRF)

Wet chemical analysis using acid digestion and ICP-MS/ICP-OES

Flowability of powders

Existing accreditations:

Accreditation according to DIN EN ISO / IEC 17025

Nadcap accreditation (Materials Testing Laboratories)

Metallic materials made from non-ferrous metals comprise a very large group of alloys that are used in numerous industries.

Classic red brass and brass alloys are familiar from sanitary installations in water pipes, fittings, and heating pipes. In some cases, new types of alloys are being developed, such as Cuphin, a lead-free material for drinking water installations that prevents the migration of lead into drinking water.

Special cobalt alloys are used for medical applications such as implants, cannulas, and prostheses. Titanium alloys or pure titanium are also used for patients who are slightly allergic to individual alloy components.

Another area of application for non-ferrous metals is

aluminum sheets. These are adapted for use as facade cladding and aluminum profiles are installed in conservatories and awnings, for example.

We check whether:

the material meets the quality requirements

why any damage occurred

the brass alloys are resistant to dezincification and stress corrosion cracking

the exterior components are weather-resistant

Fuels are used to generate energy through combustion.

They are used as fuel in transport, for example. Fuels are also used to generate electricity or heat for a wide range of applications.

The definition of fuel includes coal, lignite, hard coal, green coke and biofuels such as wood, pellets and biodiesel. The category of secondary fuels includes waste obtained from solid, liquid or gaseous materials.

In connection with the topic of fuels, the issue of CO2 emissions trading often comes to the fore.

This is a market-based instrument for reducing greenhouse gases.

In order to classify fuels, the calorific value and calorific value can be determined. This provides information about the energy content of the fuel. Furthermore, the purity can be checked by determining the trace elements.

We analyse your fuels using

Combustion analysers

Inductively coupled plasma - optical emission spectroscopy (ICP-OES)

Gas chromatography (GC)

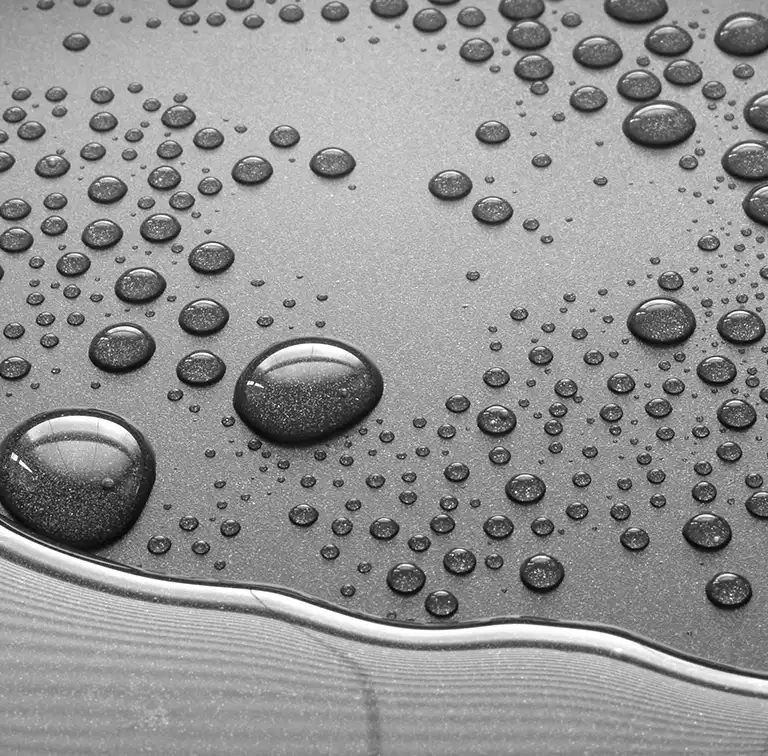

Lubricants and oils are important fluids for machines and engines that help to reduce friction, minimise wear and dissipate heat. Examples include crack detection oils, mineral oils, engine oil, gear oil and hydraulic oil. Without them, metal would move on metal, leading to rapid wear and possible damage.

Analysing these lubricants is crucial to monitor their quality and identify potential problems at an early stage. Regular oil analyses can detect impurities, wear particles and chemical changes that may indicate imminent maintenance requirements or even mechanical defects. This can prevent breakdowns, reduce maintenance costs and extend the service life of machines.

We are happy to analyse your oils and lubricants. We can use various methods for this, such as

Determination of the water content according to Karl Fischer

Density determination

Determination of the flash point

Resins and plastics have become central materials in modern industry and it is hard to imagine the sector without them.

Resins are organic polymers that can be produced synthetically (e.g. epoxy resin), are solid or semi-solid and can harden through heating or chemical reactions. They are an important component in the aerospace, automotive and many other industries.

Plastics are synthetic or semi-synthetic polymers made from petrochemicals. They are used in packaging, construction, electronics and many other industries.

We provide support in the analysis of

Styrenes and residual monomers

Leaching behaviour of insulating materials

PAHS

Plasticisers (DEHP, phthalates)

Coatings can serve many different purposes, whether for visual enhancement, corrosion protection, or insulation.

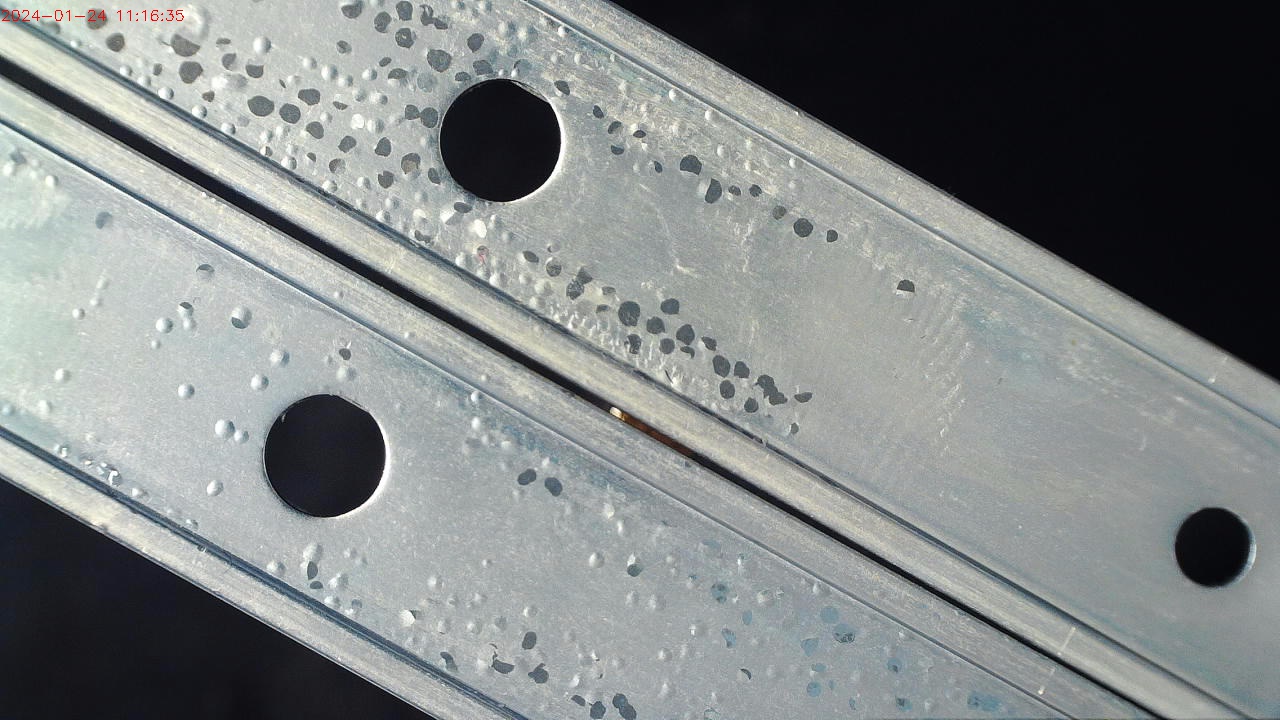

Galvanized components are often found outdoors in the form of fall protection and railings or as fastening materials. Here, the primary concern is corrosion protection.

Decoratively coated washbasin fittings or chrome-plated trim strips in the automotive industry primarily serve to enhance the appearance of base materials. Carbon coatings or ceramic coatings provide thermal and insulating functions in addition to their visual properties.

When it comes to coatings, composition is important. But evenly important is the adhesion to the base material and the resistance to external influences.

That is why we check the quality of your coatings and carry out purity tests or trace analysis.

Furthermore, plastic substrates or organic coatings may contain components that outgas at higher temperatures and can be dangerous for employees.

We have various analysis methods that can be used individually or in combination:

Microscopy, SEM-EDX

Outgassing of organic components coupled with gas chromatographic analysis

Trace analysis

Corrosion, climate, and surface tests

Adhesion strength tests

Layer analyses

Transport routes, bridges, water supply, buildings such as residential buildings or schools form the basis for many everyday activities and economic processes and are therefore crucial for the growth and development of a society.

Regular inspections of structures such as bridges or car parks, the renovation of existing buildings or the introduction of recycled building materials into structures pose enormous challenges for the construction industry.

We provide support in the analysis of

Asbestos in construction products

Determination of chlorides in concrete

Analysis of recycled materials in accordance with the German Substitute Building Materials Or dinance (EBV-RC)

Materials that can be recovered from waste and reused are known as recycled materials. These materials can come from a variety of industries.

Recycling is good for the environment and conserves our finite natural resources, as fewer primary raw materials need to be extracted. In addition, manufacturing products from recycled materials often uses less energy, which helps to protect the climate and your wallet.

Steel, for example, is melted down again and processed into new products. Glass bottles are cleaned and reused. Old electronic devices are broken down into their individual parts and the valuable components are recycled.

We provide support in the analysis of

batteries

circuit boards

Building materials

Refractory material

For enquiries about these analyses, please contact our laboratory team at anfrage@industrial-lab.de or get in touch with your contact person:

Head of department

Inorganics / Sample Preparation

02762 9740 - 74

Send e-mail

Head of Team Inorganics

02762 9740 - 93

Send e-mail

Head of department

Organics / REM

02762 9740 - 28

Send e-mail

A basic distinction is made between destructive and non-destructive testing. In non-destructive testing, the test specimen is not damaged by the test. Non-destructive testing is often carried out during production for quality control purposes or on components and materials that are inspected during use. Typical testing methods include ultrasonic testing, eddy current or X-ray measurements and visual assessments. In destructive testing, the component is damaged by the test. This damage can be partial, as in a hardness test or scratch test; it can be superficial, as in chemical tests; or it can affect the entire component, as in corrosion and climate tests.

When testing, it is important to replicate the conditions during installation or use of the materials as accurately as possible. This includes not only the test conditions but also the test specimens themselves. It is best to have components available for testing. This allows you to take into account any influences caused by material mixes or collection points that cannot be prevented on the design side. Occasionally, component groups are even used for testing in the installation. If components or component groups are not suitable for testing, test plates are usually used instead.

Material testing involves testing the material to determine whether it is suitable for its intended use. The material is tested for its mechanical, physical and chemical properties, and its suitability is assessed based on the results. The properties determined can also be used to classify and categorise an unknown material.

Resin and plastic cannot be mixed in the traditional sense. Some resins, known as reaction resins, can be mixed with a hardener and thus react to form a plastic.

Certain plastics, such as polyvinyl chloride (PVC), can be deformed or dissolved by the solvents or reaction heat in the epoxy resin.

However, there are other plastics, such as PET, that are stable when exposed to epoxy resin, especially if they are pre-treated (e.g. sanded).

Plastic and resin are closely related, but they are not the same thing. Resin is a viscous or solid substance that occurs either naturally (e.g. tree resin) or synthetically (e.g. epoxy resin, polyester resin). Plastic is an artificially produced material that may consist of resins.

The difference between oils and fats is their viscosity, i.e. their fluidity at room temperature.

Chemically speaking, oils and fats both consist of glycerine and fatty acids. The difference lies in the chain length and degree of saturation of the fatty acids. Oils are shorter-chain, usually contain unsaturated fatty acids and remain liquid at room temperature.

Fats, on the other hand, are longer-chain, contain more saturated fatty acids and are solid or semi-solid at room temperature.

The specific analysis of oil depends on the type of oil being examined. As a rule, the aim is to determine its composition, quality, impurities or ageing. This can be determined using physical and chemical parameters (such as water content, density, viscosity, flash point) or chromatographic methods (GC-MS).

Contaminants in oil usually come from water, particles (e.g. metal abrasion) or microorganisms.

Lubricant analysis is a process used to evaluate the condition and quality of lubricants (e.g. oils or greases) used in machines, engines or industrial plants. The main purpose of the analysis is to detect wear, contamination and ageing processes at an early stage so that maintenance, replacement or repairs can be planned in a targeted manner.

Possible analyses include determining the water content, density and viscosity or determining the fingerprint (as comparative GC screening).