MATERIAL ANALYTICS IN THE AREA

Steel

Steel is one of the oldest and most important materials known to humanity and is nearly infinitely recyclable. It is produced from pig iron and thus primarily consists of iron, typically containing up to 2% carbon, and is often defined as an iron-carbon alloy. Due to its low carbon content, steel can be easily cold- or hot-formed, meaning it can be bent, forged, or rolled. Iron-carbon alloys with a higher carbon content are referred to as cast iron.

Due to the raw material, iron ore, steel contains undesirable impurities such as carbon, sulfur, or phosphorus. These impurities can impart poor properties to the steel; for instance, a high carbon content makes steel brittle. Detecting and counteracting these disruptive impurities early in the process is crucial.

In addition to these unwanted impurities, other elements such as chromium or nickel are added to steel to alloy it, thus giving the steel various desired properties.

We determine the chemical composition and mineral phases of steels (low-alloy, high-alloy, chromium steel, tool steel, etc.) or unwanted phases in materials (with the same chemical composition). Additionally, we can perform plausibility checks using other analytical methods ("non-X-ray" methods).

Analysis from melt digestion, pressed powder pellets, or using non-destructive techniques

Spark-OES

XRF

Remelting of material

ICP-OES

Extensive matrix-related selection of reference materials

Qualitative or quantitative analysis

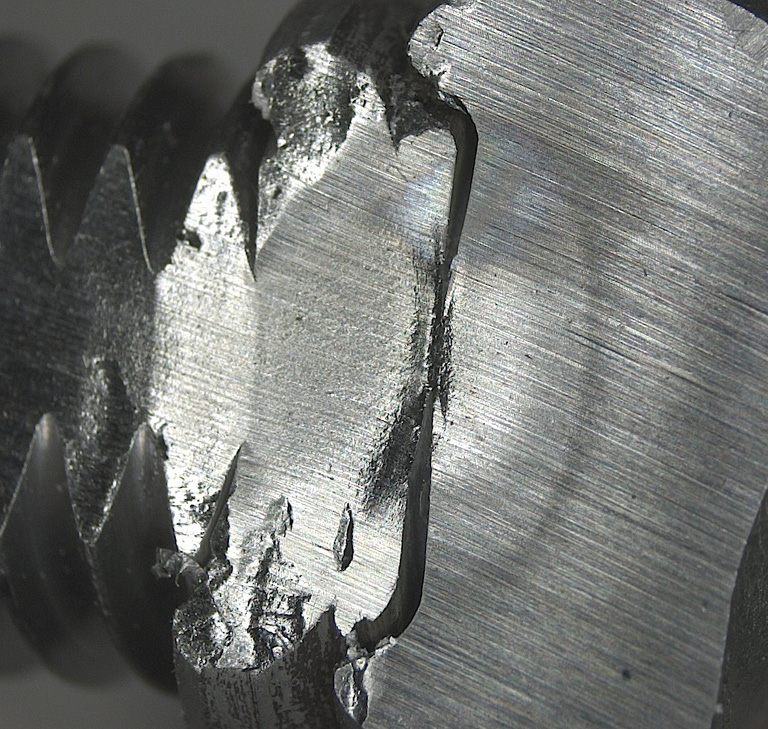

The microstructure of a metal refers to the microscopic arrangement and composition of its crystalline domains.

Microscopic examination of the microstructure provides information about the structure and, thus, the physical and chemical properties of the steel, which are significantly influenced by the types of microstructures, such as martensite, ferrite, austenite, etc., and any internal defects that may be present.

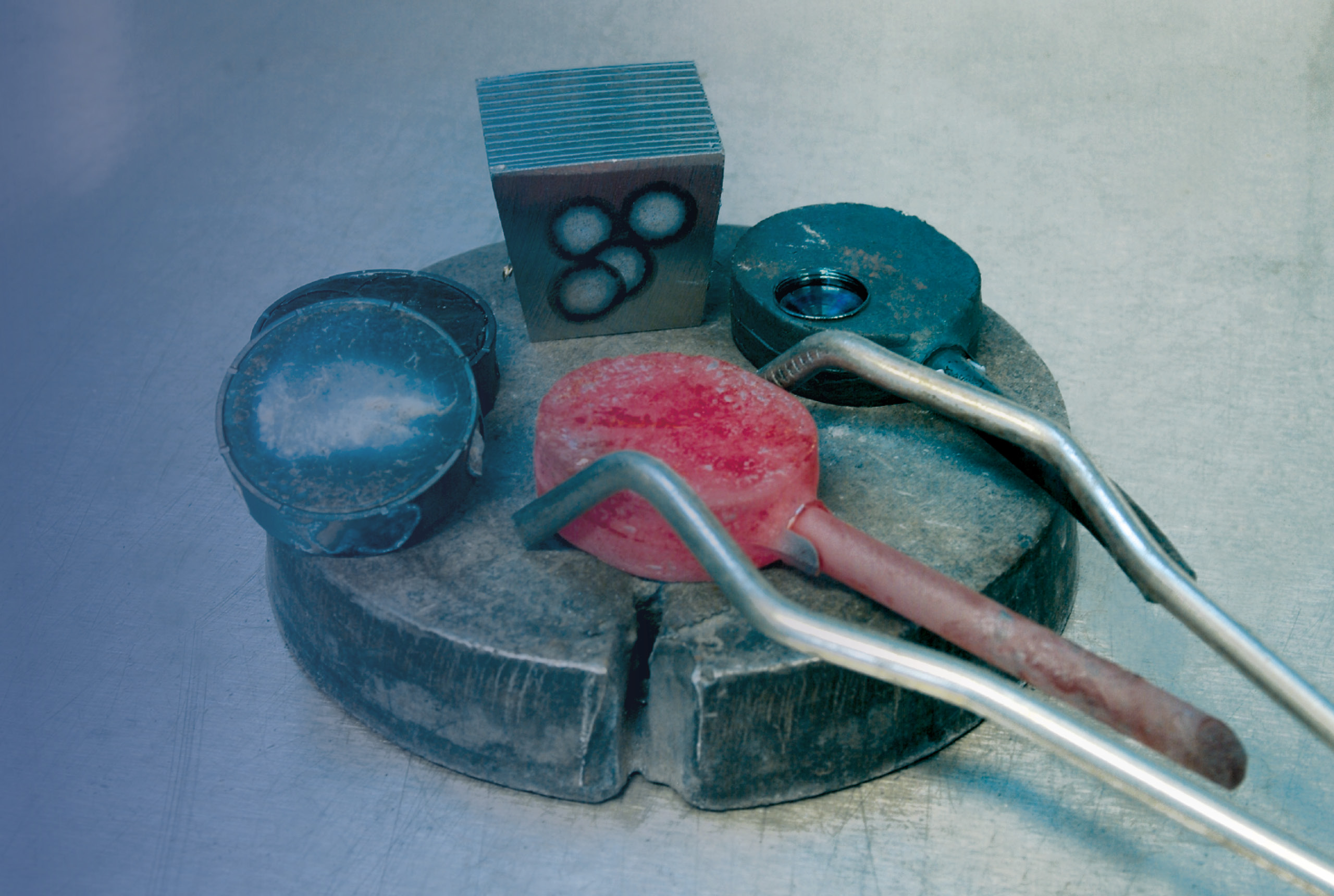

The Strauss Test is a testing procedure for high-alloy steels to assess their resistance to intergranular corrosion. Intergranular corrosion is a type of selective corrosion that occurs along the grain boundaries of the microstructure. This form of corrosion can be counteracted by a suitable alloy composition and heat treatment.

The Strauss Test examines the susceptibility of the material by subjecting it to targeted chemical and physical stress. The evaluation is then performed under a microscope.

For enquiries about these analyses, please contact our laboratory team at anfrage@industrial-lab.de or get in touch with your contact person:

Head of Team Inorganics

02762 9740 - 93

Send e-mail

Head of department

Inorganics / Sample Preparation

02762 9740 - 74

Send e-mail

Head of Department

Steel mill analytics

0151 14745337

Send e-mail

Materials tester metallography

0212 2214 - 76

Send e-mail