Surfaces & Coatings-ANALYTICS IN THE AREA

Climate and Climate Change Testing

Climate testing and climate storage are important test procedures for mapping functionality and reliability under real or simulated environmental conditions. We can simulate extreme heat or cold shocks, as well as the influence of temperature, humidity, dirt and much more on your components. We do not only refer to the automotive industry, but also to the defence and telecommunications industries, as well as to the environmental testing of aluminium facades. Different materials behave differently when exposed to cold, heat or humidity. To prevent visual or technical failures during the subsequent use of the parts and components, we test their behaviour in advance under different temperature and humidity requirements in accordance with DIN, ASTM, MIL-STD or AECTP.

During climate testing, the test parts are subjected to a defined temperature and humidity profile, which they should complete as undamaged as possible. We can not only test according to generally accepted standards, but can also test according to common AECTPs and MIL-STD using our climate chambers. In some cases, special media such as harmful gases or corrosive pastes are added to simulate real-life component use as authentically as possible. Classic tests include:

Kesternich Test

Testing in Condensation Climates

Climate Change Testing

Corrodkote and Russian Mud

The Kesternich Test works with sulphur dioxide. Sulfur dioxide is produced in combustion engines and is therefore highly relevant for all parts that are "on the road" in road traffic or in industrial halls with operational traffic and corresponding emissions. Due to emissions from road traffic, sulfur dioxide is also partly responsible for acid rain, meaning that outdoor components, such as street lamps, railings, or facade components made of aluminum or steel are also exposed to a certain degree. These are the application cases for the Kesternich Test, which simulates usage-related exposure.

In addition, sulphur dioxide has the property of making heat treatment defects in brass visible. The sanitary industry uses this property to test its brass fittings, which also undergo the Kesternich test.

Sanitary parts with brass substrates

Engine compartment parts

Rims, spokes, drive elements

Facade components made of aluminum or steel

The condensation climate tests are carried out at a temperature of 40°C and an unregulated humidity of between 95% and 100%. The humidity is unregulated because it is generated purely by the evaporation of water. This means that the test specimens also become covered in condensation water during the condensation tests. The tests are either carried out in a constant climate, in which the temperature and humidity are kept constant throughout the entire test period, or in a variable climate, in which the chamber is cyclically switched off, thereby reducing the humidity.

These tests are particularly informative for organic coatings. The humidity and warm temperature can cause paints to swell and blister, crack or chalk.

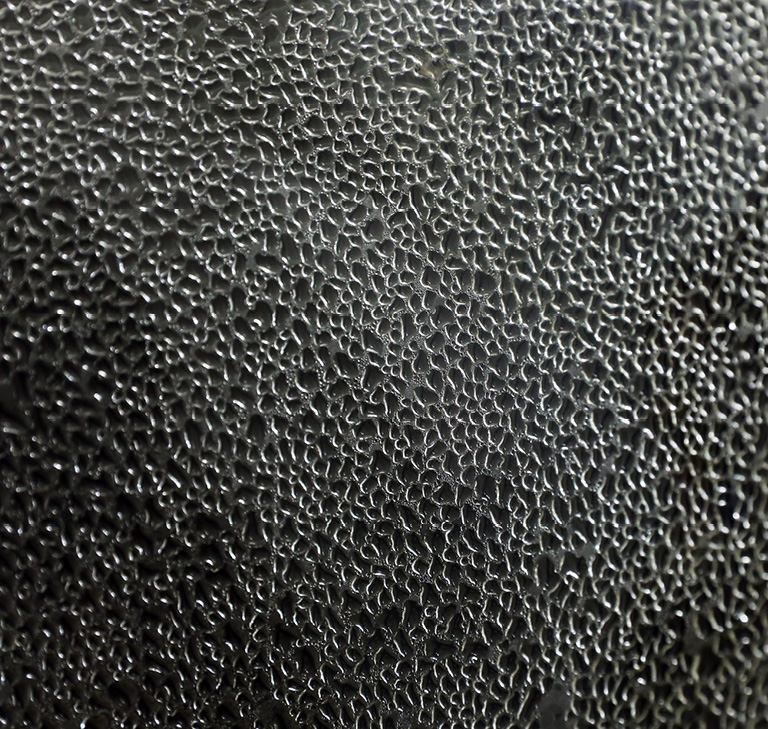

Hardened steel parts are a special application for the constant climate condensation test. In the event of hardness defects, red rust forms within 100 hours of testing due to carbide precipitation at the grain boundaries.

KTL coatings

Painted parts

Hardened steel parts

The climate change test allows us to simulate various climatic influences on your product. These environmental simulations enable us to reproduce many real or extreme conditions and thus test whether your product can withstand these conditions. In the climate change test, a specified temperature-humidity profile is automatically run through. Our high-performance climate chambers enable us to cover both common standards and individual customer requirements.

Every component is subjected to various climate changes during subsequent use. These can be rapidly changing temperature and humidity conditions, such as during the take-off and landing of aeroplanes or drones, or longer operating times for products in extreme climates such as ice and snow or desert conditions. The components must withstand all of this without losing their function.

Different materials expand differently. This must be taken into account when mixing materials. For example, if a plastic substrate is coated with metal, the substrate and coating expand differently in heat and contract differently in cold. Under these stresses, the coating must not blister or crack.

Climate change testing

Temperature shock testing

Heat storage and cold storage

Testing according to DIN, ASTM, MIL-STD or AECTP

Special applications require special tests. Even in snowy regions, cars are driven, and to keep roads clear and passable, salt is spread. The residues of snow, salt, and other road dirt accumulate on the vehicle, and in heavy snow, also around the chrome trim or emblems.

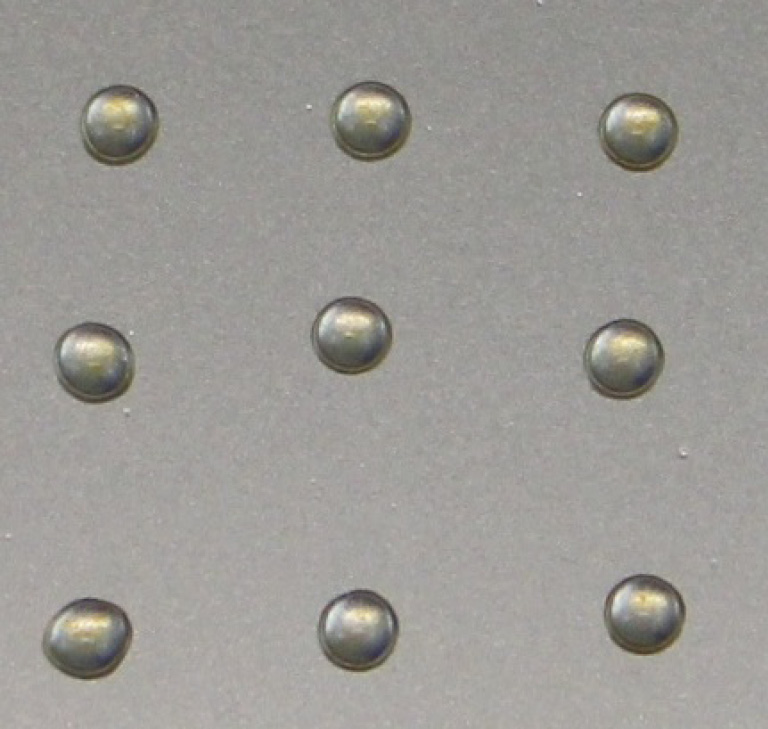

The acidic, chloride-containing mud is the ultimate enemy for the chrome layer as it literally eats away at the chrome plating. As a result, the once beautiful trim elements no longer look attractive after a winter. To prevent this from happening, a synthetic deicing solution is tested beforehand. As this problem largely occurred in Russia, the associated test is called the Russian Mud Test (ASTM B995).

The Corrodkote Test (ASTM B380) deals with dirt that can accumulate on surfaces and either affect them or cause corrosive damage. A dirt-imitating paste is applied, and the test specimens are stored in a condensation climate.

Both tests come in different variations, depending on the part’s intended application in its later life.

For enquiries about these analyses, please contact our laboratory team at anfrage@industrial-lab.de or get in touch with your contact person:

Head of Laboratory

0212 22147 - 0

Send e-mail

Electroplating technician

0212 2214 - 75

Send e-mail

phys. Technical Assistant Metallography

0212 2214 - 75

Send e-mail

In a corrosion test, the test specimens are specifically exposed to aggressive conditions that either simulate use in the component's life or are intended to specifically attack the materials. This simulates the worst case scenario for the component and checks whether the material is attacked and how severe the attack is.

Corrosion images provide important insights into the behavior of the materials and their suitability for subsequent installation. This means that any weak points can be detected before the workpiece is used and rectified after the test. This increases product safety.

The test method depends on the material of the component to be tested. Metallic components react very sensitively to chlorides and sulphur compounds. Tests are often carried out with salt spray. In most cases, a sodium chloride solution is finely atomized. The chloride-containing mist washes around the components, settles as fine droplets on the surface and attacks the metal structure. The tests are also selected according to where the component will later be used. Components that are used in a maritime climate or near the coast are specifically exposed to the salty atmosphere. Salt spray tests are also common here. Components that are used in road traffic are also tested for exhaust gas pollution caused by sulphur and nitrogen oxides. This also applies to façade components or materials in the vicinity of agricultural land that are exposed to increased levels of acid rain. There is a suitable corrosion test for every material and every material composite, depending on the area of application.

As the name suggests, climate tests simulate climatic influences. This is particularly interesting and relevant for material combinations, such as a metal-coated plastic part. Plastic and metal differ in their expansion and contraction behavior when the temperature changes. If the “chemistry” between the two materials is not right, cracks (during expansion) or bubbles or folds (during contraction) occur. However, climate tests consist not only of temperature components but also of a moisture phase. The combination of temperature and humidity is particularly challenging for organic materials, such as painted surfaces or plastics.

By exposing these materials to a defined climate, the tendency to embrittlement or, in the case of paint coatings, to blistering or chalking can be tested, for example. However, climate tests are also good indicators of heat treatment defects in steels, which show up within 100 hours as red rust on what is actually stainless steel.