Surfaces & Coatings-ANALYTICS IN THE AREA

Surface testing

Surfaces, whether coated or not, are subjected to very different types of stress - whether through environmental influences, mechanical or chemical stress, touching or wiping. Undesirable effects of this stress include damage to or mar of the surface itself, but also damage to the user himself, for example due to a nickel contact allergy. The field of surface testing is varied and complex and endeavours to cover all eventualities as appropriately as possible.

When surfaces are used and cared for, they come into contact with different substances and materials. Surfaces can be wiped dry or damp with a cotton or microfibre cloth. There are very different care products, but also media that can accidentally get onto surfaces, such as cola or hand cream. Some components are classic touch parts - door handles, scissors, gear levers or buttons on a multifunction steering wheel. Many metallic coating systems contain nickel, so it must be ensured that no nickel is released from the coating composite, to which some people react with a contact allergy. The test portfolio is enormous and the appropriate tests are selected depending on the area of application of the component. Classic tests are

Hand sweat test

Nickel leaching

Cream and media resistance

Abrasion test / Crockmeter test

Touched parts automatically come into contact with hand perspiration, which can then react with the surface and change it. The simplest change is certainly matt stains, but depending on the intensity of the contact, non-reversible attacks on the surface can occur. This applies to metallic coatings as well as paints. Of course, this is primarily an optical problem, as the function of the component is still guaranteed. However, the appearance of components and everyday objects also plays a role and is an important part of the perception of value. Roughly speaking, rusty nail scissors can still cut perfectly, but the user will not like using them.

Typical parts for the hand welding test are

Door handles

Gear lever, shift paddles

Accessories (tweezers, cuticle scissors, etc.)

Buttons and switches

We also work with a synthetic hand-sweat solution for nickel release testing. However, this test is not about assessing the surface of the test parts. Instead, the focus here is on the user. Nickel triggers a contact allergy in some people. This is a depot allergy, which means that a certain threshold value of nickel must be reached before the allergy is triggered. This tolerance value is different for each person, which is why the threshold value for nickel tolerance is set at the lowest limit.

There are two ways of testing nickel release:

After the corresponding storage times, the nickel content in the test solution is measured against a blank value and calculated for the area and the storage period.

Relevant for nickel permeability tests are

Jewellery

Door handles

Gear levers, shift paddles

Accessories (tweezers, cuticle scissors, etc.)

Buttons and switches

In the resistance tests, a distinction is made between media that are applied intentionally because they are used to care for and maintain the components. These are, for example, leather care, cockpit spray, windscreen cleaner, bathroom cleaner, polishes, etc. These media must not damage the surfaces, even if they miss the mark and, for example, the windscreen cleaner ends up on the dashboard when sprayed on. On the other hand, there are media that are not used to care for the surface, such as hand cream or sun cream on the gear knob, cola or orange juice on the trim, floor cleaner on the washbasin tap.

The potentially relevant media are brought into contact with the functional surfaces by either dripping them on, brushing them on or immersing the test specimens. After the specified exposure times, the substance is removed and the surface is examined for changes.

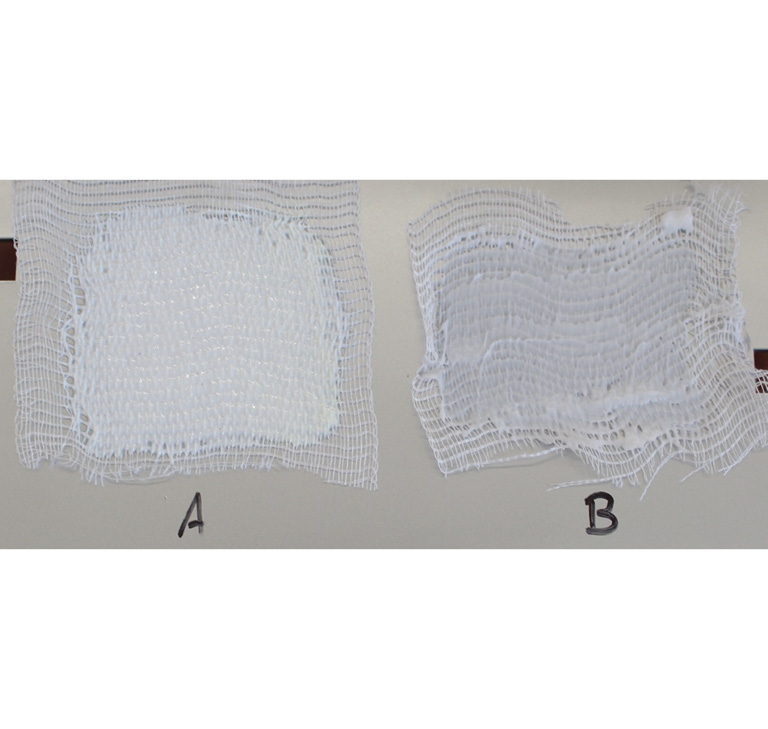

Surfaces are usually cared for by wiping them with a cotton or microfibre cloth, either dry or with a care substance. This is what we do with the tests, because the surfaces must not be affected by rubbing, of course, and that over the entire life cycle.

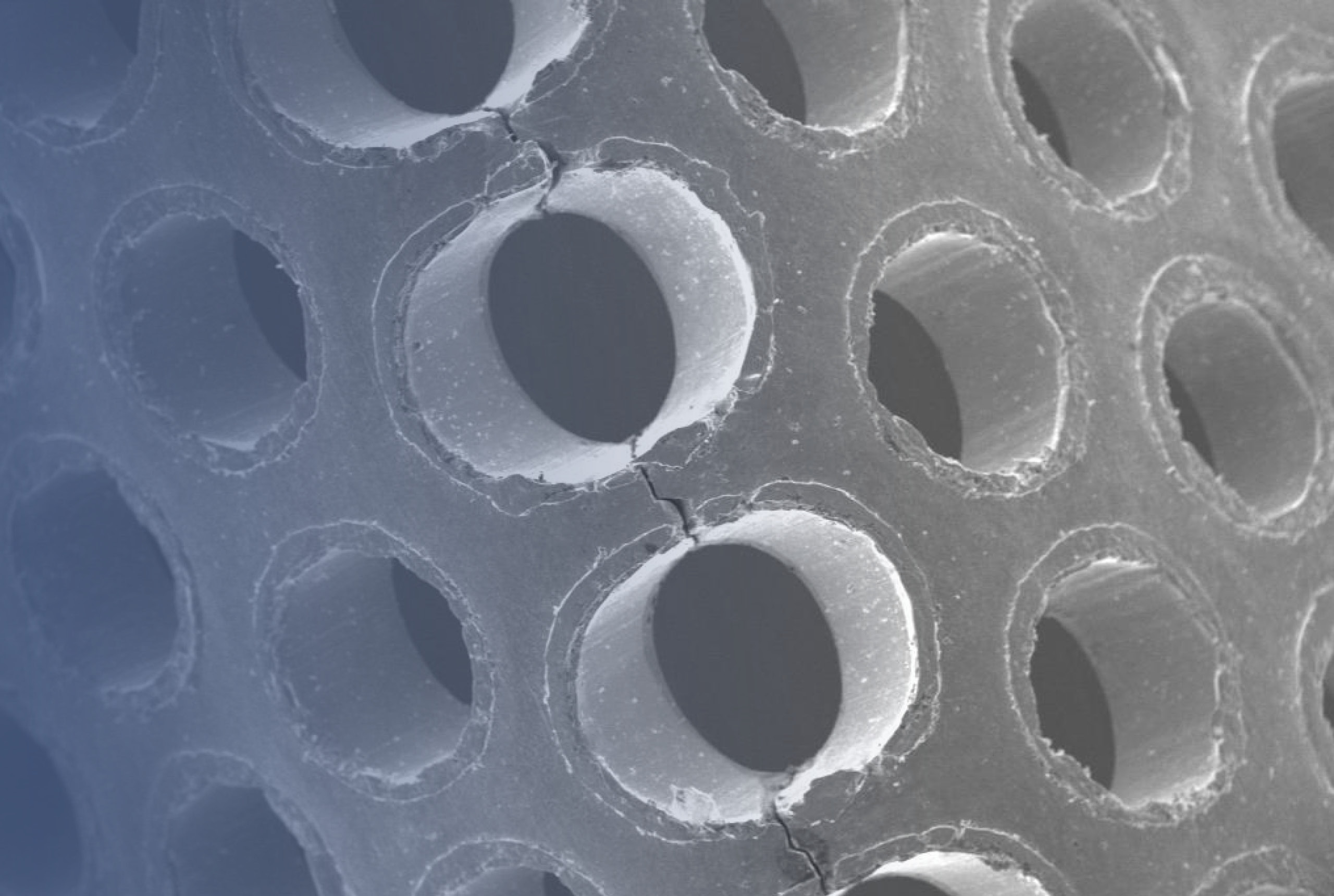

The abrasion tests are carried out using the Crockmeter. A test stamp applies a defined pressure to a standardised fabric, which is dry or wetted with the relevant medium, on the surface. This must not change visually, and the test fabric must not show any colour on the surface.

Abrasion tests are relevant for all surfaces that are cleaned by wiping.

For enquiries about these analyses, please contact our laboratory team at anfrage@industrial-lab.de or get in touch with your contact person:

BSc Chemical Engineer

0212 22147 - 5

Send e-mail

Electroplating technician

0212 2214 - 75

Send e-mail

Head of Laboratory

0212 22147 - 0

Send e-mail

When a surface is inspected optically, this is done purely visually without any aids. The inspection checks whether the surface is free of defects, homogeneous or, more generally, whether it meets the requirements. For an optical inspection, it is important to define the conditions. These include the distance, illumination, angle and, of course, time.

Surfaces are tested in a variety of ways. The simplest is certainly visual inspection, in which the surface is examined for visible abnormalities. These can take the form of bubbles, cracks, stains, flow lines, spalling, matt areas or other irregularities.

In addition, surfaces can be tested for resistance to specific media to which they may be exposed during use, such as fuels and operating fluids, cleaners or care products. There are also mechanical tests that assess the abrasion and scratch resistance of surfaces. These can also be carried out in conjunction with media.